Purifier Environmental Air for Duct

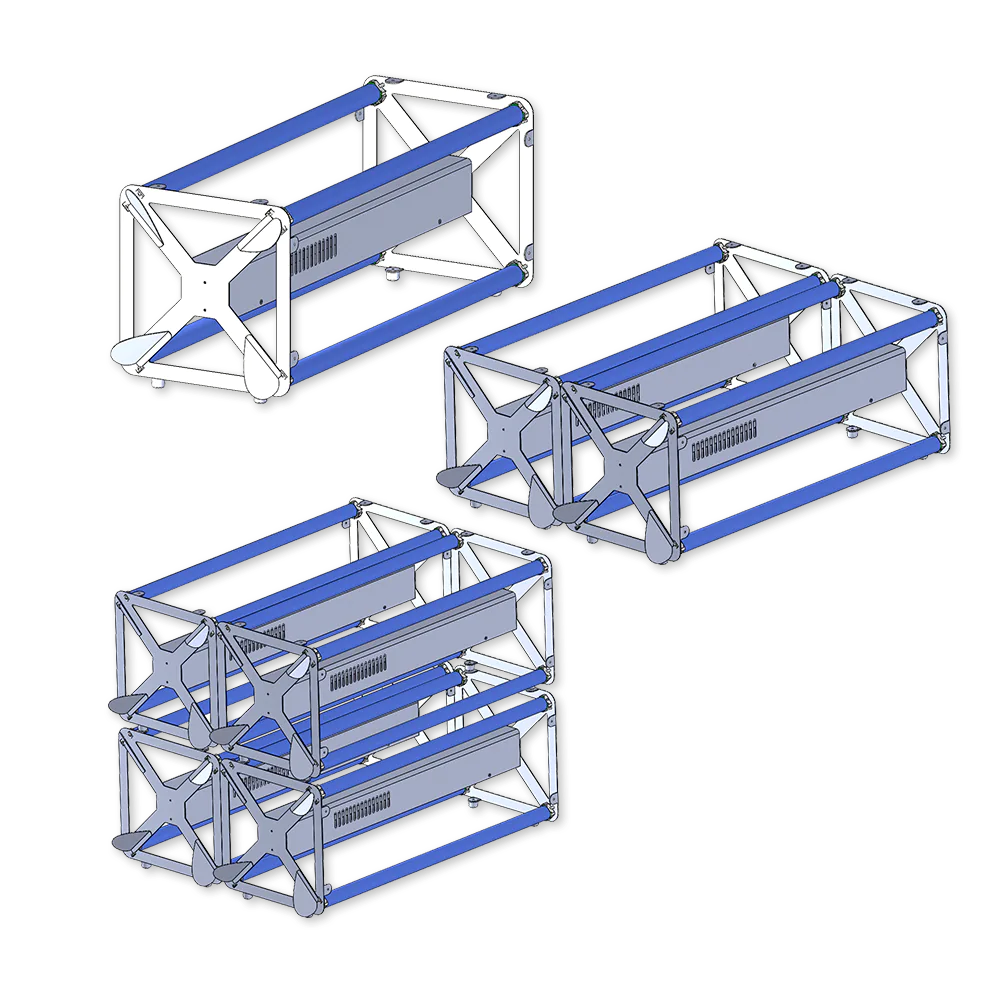

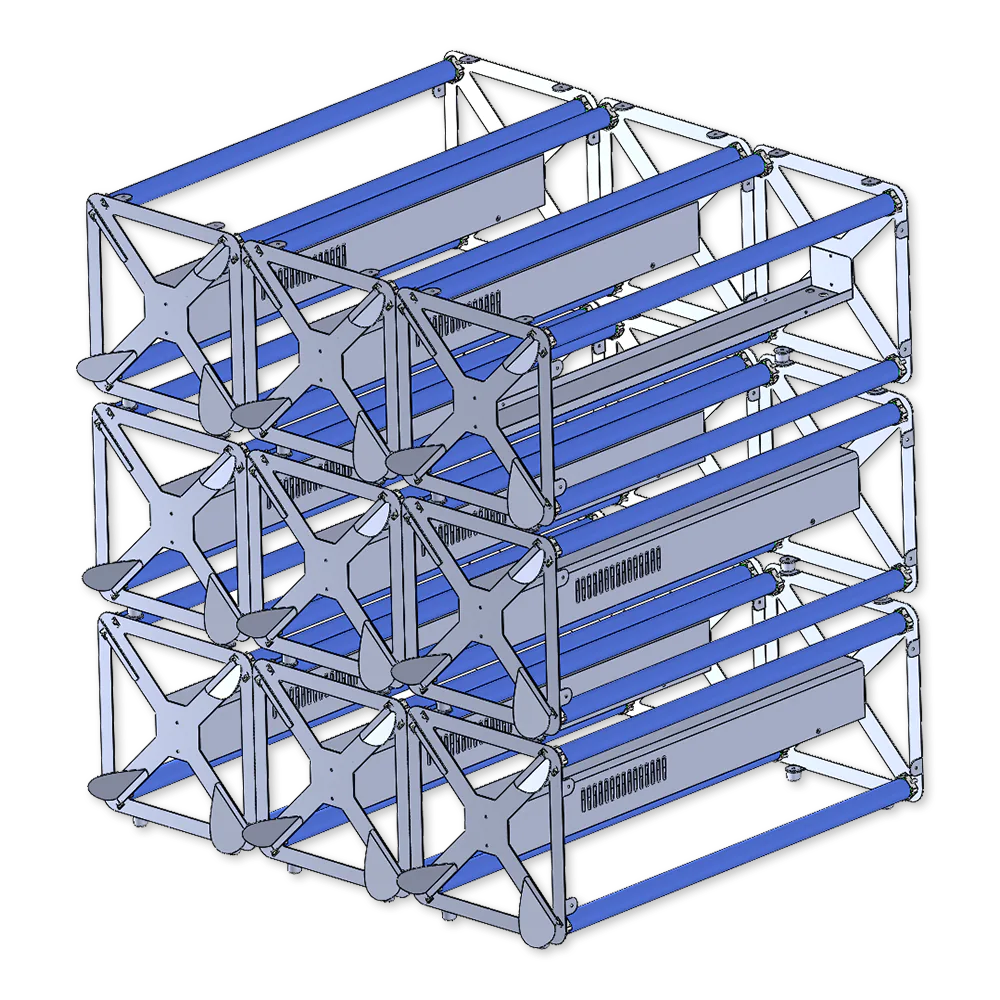

The ideal place for the installation of the equipment is the space between the exchanger/condenser and the propulsion turbine with the tubes transversal to the air passage. This place of installation brings great advantages.

1. All the air blown into the room is treated by the UVC tubes each time it is recirculated, thus quickly achieving a very high level of sterilization in a short space of time.

2. The light projected directly onto the evaporator keeps it free of microorganisms which, thanks to humidity, proliferate very easily if a containment system is not installed. The elimination of these microorganisms confers 2 great advantages;

A- The performance of the evaporator is maintained since the biological microfilm in case of not using the UVC, produces a barrier that reduces the air flow and therefore the performance of the system.

B- The colonies of pathogens formed in the condenser and the collection tray, if they are not destroyed, are driven into the pipes and later into the rooms, this untreated air being the cause of possible infections or diseases.

3. Coordination with the start-up system is easy as it can be related to the operation of the engine. If the drive motor is running, the UVC system is working, if the motor is stopped, the UVC system is turned off. For inverter machines where the motor signal cannot be used directly, it is possible to capture the operation of another point of the installation.

Are you specialized personnel or do you have a business?

Send us your query related to this product.